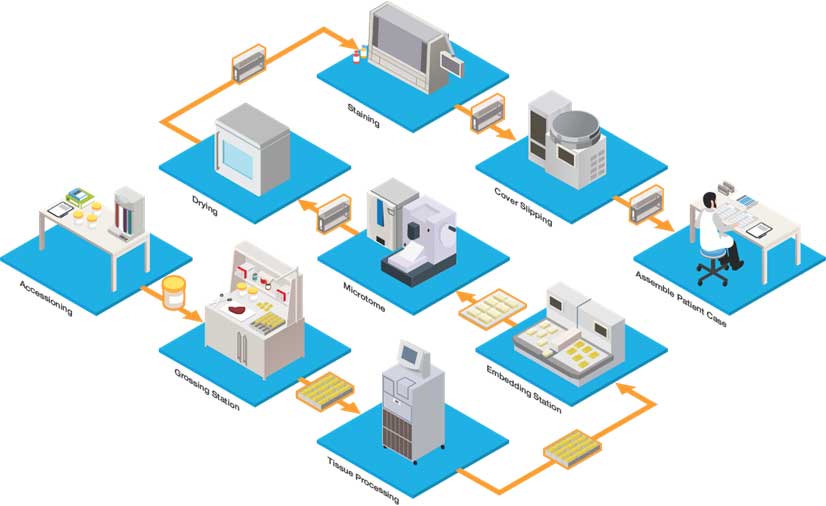

Here is how the SmartWrite System can fit in your lab for best identification and tracking

First, specimens arrive at the Tissue-Tek® Accu-Edge® grossing station equipped with the PAXcamHD Gross Imaging System and a small footprint SmartWrite® Cassette Printer with AutoLoader. Each specimen is scanned or entered into your LIS, which begins the tracking process. Since your SmartWrite Software interface has been set up to communicate with your LIS, cassette printing is completely automated and grossing photos are stored as required. Each cassette has standard identifiers printed as well as a barcode for easy lookup downstream. The cassettes are generated at your grossing station (point of generation) instead of batch printing from somewhere else in the lab, so there is no opportunity for cassettes to accidentally get swapped or ordered incorrectly which can lead to specimen misidentifications.

After the specimens go through processing and embedding, they are sent to microtomy to be sectioned. Just like the cassette printers at the grossing stations, the SmartWrite® Slide Printer has a small footprint and is designed to fit at each microtomy workstation. Simply scanning the block directly into your LIS or using the SmartWrite Software platform will bring up the case, and depending on your custom protocol setup of the software interface, the printer will automatically produce all slides needed for the case. The LIS tracks the user and/or station where each specimen was sectioned, creating another point of traceability. The information is printed directly onto the frosted area of the slide, eliminating the burden to create paper labels and the extra step of affixing them to the slides. This both creates easy-to-read slide identifiers with barcoding, and they remove the possibility of mislabeling inherent with paper or manual labeling. Furthermore, you can use the 6 different colors of the Tissue‐Tek® SmartWrite® Frosted Slides for specimen routing and sorting, for example STATs or sending to different departments / locations or pathologists.

Once cut and ready for staining, the slides are processed through the Tissue-Tek Prisma® Plus stainer linked to the Tissue-Tek Film® Coverslipper with the integrated barcode reader. As soon as the slides are coverslipped, their barcodes are scanned and sent to the LIS, giving you the ability to look up exactly when a slide was completed and ready for review by your pathologist.

Flow of specimens from accessioning to case assembly